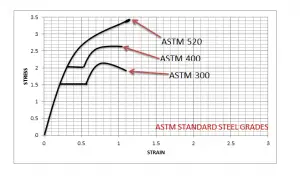

To classify various types of steel depending upon their strength. Each steel that varies has assigned a specific grade. ASTM has been provided all the specification of these grades in detail. Most common steel grades are;

- ASTM 300

- ASTM 400

- ASTM 520

ASTM 300 has the minimum elastic limit and ASTM 520 has the maximum elastic limit. With the increase of steel grades elastic limit of steel increases and in return zone of plasticity decreases. Therefore, ductility of steel decreases.

Ductility is the ability of a material to deform under applied stress before failure. When ductility of the material is higher than the building will give enough time to evacuate before collapse. Before collapsing, structure will give an indication of deformations. For Example cement starts falling from roof slab, crack propagation in the structure, crack propagation sound etc…

Pros And Cons Of Higher Steel Grade

The major benefit of higher steel grade is that the structure will behave within an elastic limit. When structure behaves like that, then no deformation will occurs in the structure. Strains that occur in a structure will vanish.

But when elastic limit increases then plastic zone decreases and now if structure goes beyond the elastic limit. Then it will not give even a little time for the evacuation of a building. Therefore, It will cause severe death.

Behavior Of Various Steel Grades

- From the graph, it is very clearly visible. Higher the steel grade, higher will be the elastic limit. But as the steel grade increases, a plastic zone of that steel decreases. Hence, Ductility of material decreases and in case if failure occurs, then it will very close to brittle failure.

- ASTM 300 steel will show maximum strains before failure.

- ASTM 520 steel fails at the same time when structure crosses the limit of the elastic limit zone.

Attractive section of content material. I just stumbled upon your weblog and in accession capital to assert that I acquire truly enjoyed account your weblog posts. Anyway I will likely be subscribing to your augment and even I achievement you access consistently swiftly. 85114