Wall footing design is carried out with some assumptions that should be considered while designing. The first assumption is to consider that soil pressure is distributed linearly throughout. This can only be achieved, when resultant of soil pressure coincides with the resultant of soil force. Because of this rotation of footing can be avoided. Generally footings are designed by following strength design method.

Wall Footing Design Example Statement

A 10” thick wall carries a service dead load of 8k/ft and service live load of 9k/ft. At the base of footing the allowable soil pressure is 5000psf and base of footing is 5’ below the existing ground surface. Now your task is to design the wall footing for;

Concrete compressive strength= f’c = 3ksi

Yield strength of steel = fy = 60ksi.

Soil density = 120lb/ft3.

Solution:

Note: Usually low strength of concrete in footing is used then that in columns. It requires the use of dowel to accommodate this strength change.

Step 1: Estimate The Size of footing and Factored Net Pressure.

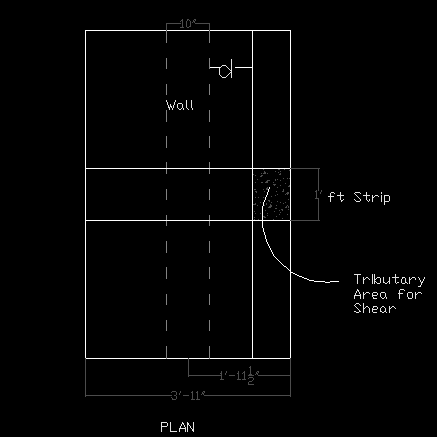

While designing wall footing, normally one feet strip of the wall and footing is considered for the sake of easiness in calculation. The allowable soil pressure is 5ksf. The allowable net soil pressure will be 5ksf. Since, the thickness of footing is not known at this stage a suitable thickness of footing equal to (1-1.5)x The wall thickness can be assumed.

1.5 x 9’’ = 13.5’’ take 13’’

Step 2: Find The Allowable Soil Pressure

\(q_{n}=5-[(1.083times 0.150)+(5-1.083)times 0.120]\)[q_{n}=4.367 ksf]

[Area-of-footing=frac{8+9}{4.3676}]

Try 47’’ (3.91’) Wide footing

Factored Net Pressure = qnet = 6.138ksf

Step 3: Check the Adequacy of Footing Depth against Shear

Only one way shear or beam shear is significant in wall footings. The critical section for this type of shear is at distance ‘d’ from the face of wall. Where ‘d’ is the effective depth of footing.

Assuming that we shall use #4 bar.

d = 13 – 3 – ¼ = 9.75″

The Tributary area for one way shear

Tributary area = Shaded area for one way shear

d = h – clear cover – 1/2 bar diameter

d = 13 – 3 -1/4

d = 9.75″

\(Tributary-Area = frac{8.75X1}{12}= 0.729ft^{2}\)Vu = qnu X Tributary Area = 6.138 X 0.729 = 4.475 k/ft

Shear Capacity

\(Shear-Capacity = o _{vc}times 2timessqrt{f’c}times b_{w}d\)[Shear-Capacity = 0.75times 2timessqrt{3000}times 2timesfrac{9.75}{1000}]

Shear Capacity = 9.618k/ft > Vu → Footing is ok against one way shear.

Step 4: Design Reinforcement for Moment

The critical section for moment is the face of the wall. Hence, moment is maximum at the face of wall. Therefore, we will find moment at that point and then a reinforcement required to cater this moment.

Tributary Area for Flexure

\(Tributary-Area= (frac{9.75″+8.75″}{12})times1′ = 1.54frac{ft^{2}}{ft}\)

[M_{u}=q_{nu}timesfrac{l^{2}}{2}]

Area of Steel Per Foot

\(M_{u}=o M_{n}\)→

\(M_{u}=o A_{s}f_{y}times{0.9d}\)→Footings are generally reinforced structure, so jd can be taken as 0.9d.

\(7.294times 12000=0.9times A_{s}times60,000times({0.9times9.75})\)→

\(A_{s}= 0.184frac{in^{2}}{ft}\)Now compare it with this Area of steel corresponding to ρmin

ρmin = Temperature and Shrinkage reinforcement

ρ = 0.0018 for Grade 60 steel

\((A_{s})_{min}=rho_{min} times btimes h\)[(A_{s})_{min}=0.0018times 12times 13 ]

\((A_{s})_{min}= 0.2808 frac{in^{2}}{ft}\)ρmin governs. Hence, provide area equal to ρmin reinforcement 0.2808 square inch per feet.

Provide #4 @ 81/2″ C/C

→Maximum Bar spacing = 24″ or 18″

Step 5: Check Development Length

Development length value can be checked from ACI Code 318-M table A-11. Corresponding to #4 bar and 3000Psi concrete compressive strength. The value of development length is 43.8″.

\(l_{d}= 43.8/times 0.5\)→21.4″

Find the distance from the mid of the wall to the end of bar;

Distance = 23.5 – 3 = 20.5″ <21.4″ → Ok

Also provide hooks at the end of wall or you can also increase width of footing. Provide 180° hook.

Similarly, select minimum temperature and shrinkage reinforcement in the other direction.

\((A_{s})_{min}= 0.2808frac{in^{2}}{ft}\)Provide #4 @ 8 1/2″ Center to center