How structure will perform when it goes under load? It’s all depends on the type of stress, stress strain relationship and the properties of the material from which it is made. The stress – strain relationship has an importance in which material is stronger. As concrete is stronger in compression, that’s why its compressive stress-strain curve is of major concern.

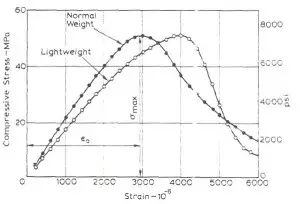

The stress – strain relationship of a material can be obtained from the cylinder test measurements which are conducted normally in 28 days old concrete. Relationship varies with the variation in concrete density. At the start every material goes straight, showing the closely proportional relationship of stress and strain. Time reaches when the curve begins to horizontal until maximum stress, i.e., the compressive strength of concrete where strain ranges from about 0.002- 0.003. This case was for normal density concrete. In case of lightweight concrete maximum stress point comes until strains ranges from about 0.003- 0.0035.

Compressive strength value goes bigger for high strength concrete with less number of strains. After attaining peak a recession branch starts proceeding in a downward direction. After the curves peak, the characteristics of the curves depends on the testing method. If stress rate is constant, then long downhill steady branches will be obtained. Incase stress rate is not the same then the curve after peak ends very rapidly. In case of high strength concrete, unloading point will be even more rapid. This is because; high strength concrete is generally more brittle than normal strength concrete. As strength goes high, concrete will become more brittle and henceforth, less number of strains a material absorb before failure.

Generally for normal strength concrete, the ACI specified compressive strength ranges from 3000 to 5000 Psi. Concrete with compressive strength ranges from 8000 to 12000 Psi is generally categorized as a high strength concrete. High strength concrete is used in the columns construction of high rise buildings, offshore and for long span bridges. High strength concrete decreases the dead load of a structure and also it saves valuable floor space by a small cross section of columns.

Modulus of elasticity “the slope of the initial tangent straight line” depends on the strength of the material. In case of high strength concrete, it is seen to be larger. This is because, a high strength concrete has less number of strains before failure. High strength concrete absorbs more loading effect then normal concrete. Its curve grows more in a vertical direction than horizontal. ACI has mentioned an empirical equation in code, for the material having compressive strength ranges to about 6000 Psi. This is for the accuracy of final curve results.

where;

- Wc is the unit weight of the concrete

- fc is the compressive strength of concrete in Psi.