Concrete under water is a very delicate operation because inaccurately carried out concreting creates very serious problems. That’s the reason, experienced persons are required for under water concreting. There are following tips for better placement and for better results of underwater concreting.

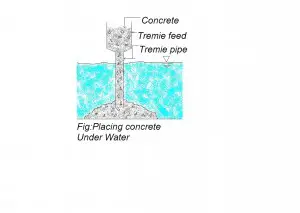

- During the underwater placing, it must be ensure that concrete should not be washout by the water. Concrete should be designed such that it provides resistance against cement washout. Concrete can be protected from washing by using tremie method of concreting. In this method concrete is poured in to a steel pipe that was already buried with the previous concreting. This steel pipe is the tremie.

- Under water concrete should have a better slump value that lies within the range of 6 to 10in. This is so, because continued concreting under water flow laterally and loose homogeneity. For better results make arrangements of anti-washout admixtures. Anti-washout admixtures are very effective as they able the concrete to flow during pumping. Anti-washout admixtures make concrete highly viscous when it is at rest. Anti-washout admixtures are preferred during turbulent underwater conditions.

- Concrete mix should contain high amount of cementitious materials that lie within the range about 360 to 400 kilograms per cubic meter.

- Underwater concrete should also contain 15 to 20 percent pozzolans. As pozzolans improves the fluidity of concrete which in returns improves the concrete workability.

- Before discharging into the tremie pipe, pre-cooled the concrete to 4 Celsius. Because if pouring is to be done on large area then concrete temperature reaches about 70 to 90 Celsius near the center of concrete. This imposes cracking in concrete as it cools down. Cracks become even more prominent in situation concrete is unreinforced.

- The two scientists Gerwick and Holland who comes with a solution of concrete cracking. They suggest that the use of blended cement that also carries 16 percent Portland cement, 78% slag and 6% silica fume reduce the probability of cracking in concrete on hardening.

- Water to cement ratio is another aspect that should also be consider. It should be about 0.40 to 0.45.